Artificial intelligence is taking every industry by storm; 78% of organizations use AI in at least one business function. In the world of shipping and logistics, AI has a major role to play, and the companies that embrace it early will have a decided advantage over those who drag their feet.

Of course, concerns about AI—high costs, technical implementation challenges, and change management—are valid. But when companies approach AI the right way, the ROI can be astronomical.

In this article, we’ll break down the benefits of AI in logistics and share practical examples of how companies can use it to optimize their operations.

Note: This article will include insights from Unboxing Logistics guests about the benefits of AI in logistics, tips for getting started, and specific tasks AI can help with.

Key takeaways

- Artificial intelligence in logistics and supply chain helps businesses make faster, data-driven decisions across warehousing, fulfillment, and shipping.

- Key benefits of AI include cost reduction, enhanced visibility, improved accuracy, and reduced risks.

- AI tools address challenges like capacity limits, last-mile delivery costs, shifting customer expectations, and supply chain disruptions.

- EasyPost’s Shipping API makes it simple to adopt a multi-carrier strategy, while Luma uses AI to analyze shipment history and recommend the best carrier mix.

What is AI in logistics?

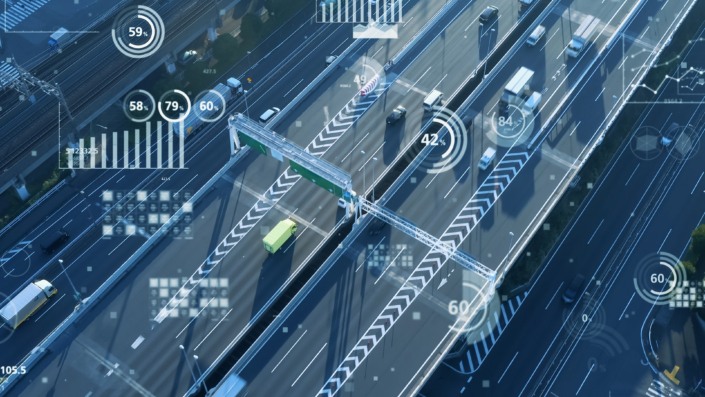

AI in logistics is the use of artificial intelligence technologies—such as machine learning, predictive analytics, and automation tools—to improve how goods move through the supply chain.

The problem with traditional logistics

Traditionally, logistics teams have relied on manual processes or legacy technology to make decisions about inventory, warehousing, fulfillment, and transportation.

When people make all the choices—and manually perform routine tasks like data entry—errors are common and costly. While technology speeds things up, many businesses still use outdated systems that don’t easily scale as shipping volume grows.

The way forward

The solution? Using modern AI technology to make faster, data-driven decisions that adapt to real-world conditions.

In practice, this can mean forecasting demand more accurately, optimizing delivery routes, automating warehouse tasks, or analyzing shipping data to cut costs and improve service.

One thing to keep in mind—investing in AI can seem overwhelming (and expensive), but it doesn’t have to be that way. By identifying specific problems to address with AI solutions, you can see meaningful results with minimal spend.

“AI tools are more agile now, so you can target the operation that is important for you to automate. I don’t think we should think about AI as … implement[ing] full-scale robotics. I think you can focus AI on tools related to, let’s say, inventory management, or demand forecasting, or … optimizing your storage. And by focusing on these … smaller cogs in the warehouse, you don’t need massive amounts of investments to get up and running.” — Henrik Bergsager

Benefits of AI in logistics operations

By incorporating AI into your logistics operations, you can cut costs, improve visibility, make data-driven decisions, and reduce risk. Let’s explore each benefit in more detail.

1. Lower costs, greater operational efficiency

One of the most direct benefits of AI in logistics is lower costs, a perk that goes hand in hand with increased efficiency.

Because AI can quickly process huge amounts of data, it excels in identifying waste in processes—such as unused warehouse space, inefficient routes, or high fuel usage—that might otherwise go unnoticed.

Additionally, AI helps automate repetitive tasks like shipment tracking, helping shippers cut down on labor-intensive work and free up staff for higher-value responsibilities. Over time, these improvements add up to significant savings.

For example, EasyPost’s AI tool, Luma, analyzes historical shipping data to identify which carriers and services provide the quickest, most cost-effective delivery. By adjusting their carrier mix accordingly, shippers see drastically lower costs.

Tom Butt, EasyPost’s AI expert, shares some typical results: “We’re seeing anything from [savings of] a couple percentage points [to savings of 25%]. For somebody that’s shipping a lot of volume, [a] few percentage [points] might be tens of thousands, hundreds of thousands of dollars a month. We see some customers [who are] only using a single carrier right now and want to expand to a multi-carrier service. They could save up to 25%.”

2: Enhanced supply chain visibility

AI helps provide greater visibility from the first to the last mile, making it easier to create an effective supply chain strategy and pivot when issues arise.

Instead of relying on fragmented data from multiple systems, AI platforms can collect and analyze information across carriers, warehouses, and customer orders. This real-time view allows businesses to quickly identify shipping delays, inventory shortages, or cost spikes before they grow into larger problems.

Greater visibility also supports more accurate customer updates, which is especially valuable during peak seasons when shipping delays are common.

3. Improved accuracy and decision-making

Logistics decisions shouldn’t be based on a hunch.

AI reduces guesswork by analyzing historical data along with real-time conditions. Based on its analysis, an AI tool might help predict demand more accurately, recommend stocking levels, or identify the best fulfillment center to ship from for a particular order.

With data-driven decision-making, businesses avoid expensive mistakes like overstocking, understocking, or choosing an inefficient shipping method.

And as you know, better day-to-day decisions lay the foundation for long-term growth.

4. Safety improvements and risk reduction

AI is also being used to improve safety for both workers and goods in transit.

In warehouses, AI-powered robotics and vision systems reduce the risk of workplace injuries by automating heavy lifting or flagging unsafe conditions. On the transportation side, AI can monitor driver behavior, vehicle performance, and road conditions to prevent accidents and reduce liability.

And these safety-focused applications don’t just protect employees—they also prevent expensive disruptions. By reducing both human and equipment-related risks, organizations can keep their operations running smoothly while also protecting their workforce.

The multi-carrier optimization strategy

Before diving into some of the logistics challenges AI can solve, we’ll look at one example of how parcel shippers can use AI technology to save money and keep their operations running smoothly.

What does AI logistics look like for parcel shipping?

In his Unboxing Logistics episode, Ben Gordon explained, “AI-powered analytical work [can reveal] that some carriers do a better job for you in certain situations, [allowing you to] allocate the right orders to the right carriers at the right time.”

It’s worth saying again: you need to assign the right orders to the right carriers at the right time. And AI makes it simple.

EasyPost and Luma

Relying on just one or two carriers can leave a business exposed to higher costs and unexpected disruptions. If a carrier raises rates, faces delays, or runs into capacity issues, shippers with limited options often have no backup plan.

That’s where EasyPost comes in. Using the Shipping API, businesses can quickly connect to dozens of carriers, giving them the flexibility to spread volume, compare rates in real time, and reduce dependence on any single provider.

Luma builds on that foundation by using AI to analyze a business’s own shipping history (and even that of similar-sized shippers). It then highlights where cost savings and performance improvements are most likely, considers your customized shipping rules, and automatically puts its suggestions into action.

For example, Luma might show that a certain carrier’s ground service delivers in two days 90% of the time. By using the ground service instead of a more expensive two-day service, you’ll save money and give your customers the fast delivery experience they crave.

The result is a smarter, more resilient shipping strategy.

How AI helps with logistics challenges

While many aspects of logistics are interpersonal—like developing a good relationship with suppliers or handling customer complaints one-on-one—much of this industry deals with hard data.

Fortunately, AI can help with both sides of things.

“AI has the capacity to totally transform not just logistics, but everything. But particularly logistics because AI is outstanding in areas that, one, are process intensive, and … two, [are] document intensive. … There’s a lot of data workflow processes and transaction intensity.” — Ben Gordon

Addressing capacity constraints

AI helps businesses manage limited carrier or warehouse capacity by analyzing historical shipping data and current demand to forecast when space will be tight.

With these predictions, companies can shift shipments earlier, spread volume across multiple carriers, or adjust inventory placement to prevent bottlenecks.

Managing last-mile delivery complexities

Ah, the dreaded last mile!

The last mile of shipping is the most expensive and unpredictable part of logistics—and it can make or break the customer experience.

That’s why many businesses are now using AI to optimize last-mile delivery, reducing both delays and costs. With a tool like Luma, it’s easy to measure carrier performance, automatically select the fastest and most affordable shipping services, and flag issues like lost or damaged packages.

Adapting to customer expectations

Customers expect fast, accurate delivery updates and flexible options at checkout. AI supports this by personalizing shipping recommendations and providing real-time tracking visibility. For instance, a system might automatically offer the most reliable delivery options at checkout, ensuring customers get accurate delivery dates without overpromising.

Measuring carrier performance

AI can evaluate carrier performance beyond just cost, factoring in things like on-time delivery rates and damage claims. And when paired with a multi-carrier API like EasyPost, an AI system can get super specific about which carriers perform best in certain regions.

By continuously monitoring these metrics, businesses can make more informed decisions about where to allocate shipments. For example, AI might reveal that one carrier consistently underperforms in a certain region, allowing the shipper to shift volume elsewhere.

Responding to supply chain disruptions

When weather, labor strikes, or geopolitical issues disrupt the supply chain, AI helps businesses adapt quickly.

By analyzing real-time conditions, AI can reroute shipments, recommend alternate carriers, or even suggest adjusting fulfillment centers. This minimizes delays and turns unexpected events from full-scale logistics nightmares to small hiccups.

Balancing cost, speed, and reliability

Every shipment involves tradeoffs between affordability, delivery time, and service quality. AI helps balance these priorities by modeling different shipping scenarios and recommending the option that best fits a business’s goals.

Take the next step in optimizing your logistics operations

Adopting AI for logistics operations doesn’t have to be complicated. With EasyPost and Luma, you can get up and running in no time!

“[One mistake businesses often make] is not getting started. [They] say, ‘Hey, I don’t know this. We’ll wait for others to get this figured out.’ I can tell you right now, there’s not going to be a starting gun. And those that adopt AI and start to build it into some methodologies, build it into frameworks, are going to have a head start and a leg up.” — Tom Butt

Harnessing the power of AI to make smarter parcel shipping decisions will help you save time and money, get a better picture of your shipping success (and setbacks), and continue to delight customers.

Optimize your shipping strategy with Luma

Reduce risk and cost by finding the best carrier mix with AI insights from your shipment history.