Businesses have a lot riding on the efficiency of their warehouses. When things don’t run smoothly, they face delays, bottlenecks, and customer dissatisfaction. And even small inefficiencies and mistakes lead to higher operating costs that cut into profits.

The future of warehousing efficiency lies in an emerging technology: artificial intelligence. What is an AI warehouse capable of in 2025 and beyond? Let’s dive in.

What is an AI warehouse?

An artificial intelligence warehouse, or AI warehouse, is a logistics facility that uses artificial intelligence to automate processes that once had to be done manually. With AI, organizations can optimize procurement, shipping, and everything in between.

Modern warehouses house hundreds or thousands of different products. Manually managing the movement of products in and out of these facilities is complex and often results in expensive errors.

AI turns complexity into simplicity, surfacing insights and recommendations to help warehouse managers make meaningful operational improvements.

By using AI in warehouse management, businesses put a resource they already have—their data—to work for them. With better insights into fulfillment activities, logistics leaders can make smarter decisions that improve inventory management, picking and packing, shipping, and more.

Key ways AI technology is used in warehouses

Two of the top reasons why retailers are incorporating AI into their supply chain are improving operational efficiency (58%) and reducing costs (45%). AI technology can be used in the following ways to achieve these objectives.

Warehouse layout optimization

Are you using your warehouse space as effectively as possible? AI can answer that question!

AI systems help businesses design and refine warehouse layouts to reduce travel time, minimize congestion, and improve overall flow. They do this by analyzing historical order data, worker movement, and equipment usage to identify bottlenecks and inefficiencies. As demand patterns shift, AI can suggest updates that keep goods moving seamlessly.

AI tools for warehouse layout optimization include the following:

- AI-powered simulation software creates digital twins of warehouse layouts, allowing businesses to test different configurations before making physical changes.

- Machine learning algorithms analyze order frequency, item velocity, and travel distances to recommend optimal storage locations.

- Predictive analytics forecasts demand fluctuations and suggests adjustments to prevent congestion and streamline picking routes.

- Computer vision systems monitor worker movement and equipment paths, identifying places where layout changes could reduce bottlenecks.

Receiving and sorting

When integrated with barcode scanners, RFID systems, and robotic sorting equipment, AI helps to create a seamless intake process. Rather than relying on manual checks and sorting, you can use AI-powered systems to instantly identify, categorize, and direct incoming inventory with little human intervention.

AI tools for receiving and sorting include the following:

- Computer vision systems identify packages, scan labels, and detect damage upon arrival.

- AI-driven sortation algorithms automatically categorize incoming shipments based on item type, priority, or storage location.

- Robotic sorting systems work together with AI to scan, pick, and route items efficiently.

Demand forecasting

Stockouts and overstocking are some of the most costly warehouse inefficiencies, and AI can help reduce or even eliminate them. It does this by generating precise demand predictions based on historical sales data, market trends, and external factors like weather or economic shifts.

AI tools for demand forecasting include the following:

- Machine learning algorithms continuously refine forecasts based on sales trends, customer behavior, and seasonal patterns.

- Predictive analytics combines real-time and historical data to anticipate demand fluctuations and prevent over- or under-stocking.

- External data integration allows AI to pull in economic indicators, weather patterns, and even social trends to refine forecasts.

Inventory management

Warehouse AI enhances inventory management by providing real-time visibility, reducing shrinkage, and optimizing stock levels.

While traditional inventory tracking relies on periodic counts and reactive adjustments, AI continuously monitors stock, predicts shortages, and suggests replenishment strategies. It integrates with RFID, IoT sensors, and warehouse management systems (WMS) to keep inventory levels accurate and up to date.

AI tools for inventory management include the following:

- Computer vision systems track stock levels in real time using cameras and image recognition, reducing the need for manual cycle counts.

- RFID and IoT-powered AI tools automate inventory tracking with smart tags and sensors that instantly update stock data.

- AI-driven dynamic slotting adjusts storage locations based on picking frequency, minimizing travel time and improving efficiency.

- Automated replenishment systems use AI to trigger restocking orders when inventory hits predefined thresholds.

Order fulfillment

AI makes the order fulfillment process faster, more accurate, and more efficient. From the moment an order is placed to the time it leaves the warehouse, AI systems can help optimize every step, making sure products reach customers as quickly as possible.

Picking

AI can analyze order data and warehouse layouts to generate the most efficient picking paths. It also works with robotic picking systems to automate retrieval.

AI tools for picking include the following:

- AI-driven route optimization determines the fastest picking paths to reduce travel time and improve efficiency.

- Vision-guided picking systems use augmented reality (AR) or wearable AI to guide workers to the right items.

- AI-powered robotic arms and autonomous vehicles retrieve items with speed and precision.

Packing

AI ensures that items are packed correctly, efficiently, and in the most cost-effective way. It determines the best box size, reduces packing material waste, and verifies package contents to minimize errors.

AI tools for packing include the following:

- Automated dimensioning systems calculate the optimal box size based on item dimensions and fragility.

- Computer vision adds an extra layer of quality control, scanning packed orders to verify contents and detect errors.

- AI-powered packing algorithms recommend the best packing configurations to minimize damage and reduce shipping costs.

Shipping

AI makes it easy to select the best carrier and shipping service for every order, leading to on-time deliveries without high shipping costs.

AI tools for shipping include the following:

- AI-powered carrier selection chooses the most cost-effective and efficient shipping option based on delivery time and cost.

- Route optimization algorithms improve last-mile delivery efficiency by adjusting routes based on traffic and weather conditions.

- Predictive shipping analytics anticipates delays and reroutes shipments to avoid disruptions.

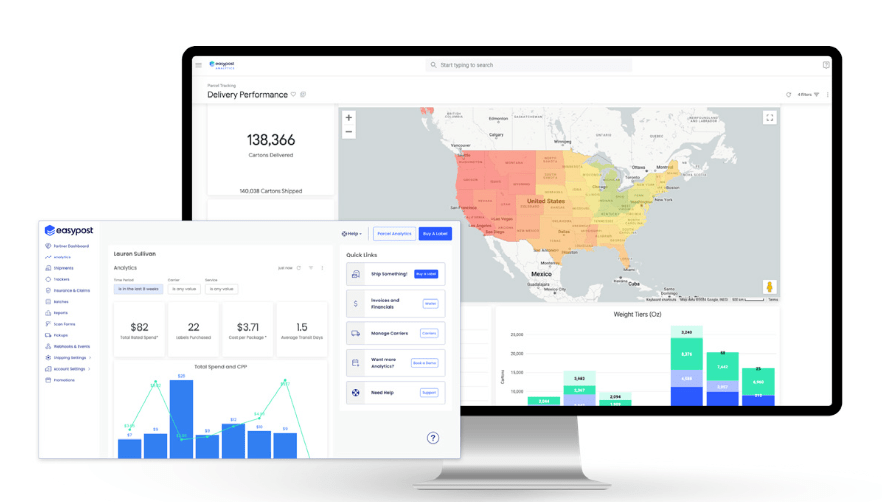

If parcel shipping is a pain point in your warehouses, check out EasyPost Luma. Luma is an AI shipping solution that helps businesses understand what’s working (and what’s not) in their current shipping strategy, provides time- and money-saving recommendations, and automatically implements those recommendations to select the best label every time.

Workforce management

With labor costs higher than ever (and on the rise), warehouse managers need a way to make sure they’re using labor as effectively as possible. That’s where AI comes in! AI workforce management solutions can predict demand fluctuations, determine how many workers are necessary at any given time, and create optimized schedules to avoid overstaffing.

AI tools for workforce management include the following:

- AI-powered scheduling systems adjust staffing levels based on order volume, seasonal trends, and productivity data.

- AI-driven task allocation assigns tasks based on worker skill levels, availability, and workload to maximize efficiency.

- Wearable AI and computer vision monitor worker movements to reduce fatigue, prevent injuries, and improve ergonomics.

Predictive maintenance

Warehouse equipment failures can shut down operations for hours, leading to package delays and thousands of dollars lost to labor costs as pickers and packers stand around with nothing to do.

AI helps prevent unexpected shutdowns by analyzing data from sensors, machinery, and historical maintenance records to predict equipment failures before they happen.

With early signs of wear and tear brought to their attention, warehouse managers can proactively schedule equipment checks or repairs.

AI tools for predictive maintenance include the following:

- Machine learning algorithms analyze past equipment failures to predict when maintenance is needed.

- IoT-enabled sensors continuously monitor vibrations, temperature, and performance metrics to detect early signs of malfunction.

- Computer vision uses cameras and AI to detect visible signs of wear or damage on conveyors, forklifts, and other machinery.

Benefits of AI warehousing

Using AI for warehouse management has many benefits; let’s look at just a few.

1. Automated processes

AI automates repetitive, time-consuming tasks like picking, sorting, and packing, so your team can focus on higher-value work. This not only speeds things up but also improves consistency and accuracy.

2. Predictive decision-making

Instead of waiting for issues to arise, AI helps you stay ahead of the game by predicting future demand, inventory needs, and maintenance requirements. With AI doing the heavy lifting of data analysis, logistics leaders have more bandwidth to make smarter, more proactive decisions.

3. Improved accuracy

In warehouses, even small mistakes can lead to wasted time. AI helps minimize errors and boost productivity by improving the accuracy of order picking, inventory tracking, and quality checks.

4. Cost savings

Just as AI saves time, it also saves money for businesses. From optimizing labor and energy use to reducing waste and overstocking, AI helps cut down operational costs. By not overspending on unnecessary resources, your business can invest more in growth.

5. Better operational visibility

With AI, you get a clear view of everything happening in your warehouse. Real-time dashboards and data analytics help you track inventory, monitor team performance, and spot potential issues before they become major problems.

6. Real-time issue management

When things go wrong (and let’s face it, they will), AI spots the problem instantly and can even recommend fixes. Whether it’s an inventory glitch or a machinery breakdown, AI systems can help you tackle issues before they escalate.

7. Competitive insights

AI can give you a leg up on the competition by analyzing trends, customer behavior, and even your competitors’ movements.

With these insights, you can make better strategic decisions about inventory, pricing, and fulfillment to stay ahead in a fast-paced market.

Getting started with AI warehouse technology

Now you know the uses and benefits of AI warehouse technology—but how should you get started? Some organizations hesitate to automate their warehouses with AI because of the upfront costs and potential implementation challenges.

However, getting started with AI and other automation technologies doesn’t necessarily require a full warehouse redesign. Instead of trying to implement multiple solutions at once, choose one or two pain points to address first.

For example, many merchants struggle with high parcel shipping costs. With so many carriers to choose from, it’s tricky to know which carrier and service level will provide the best balance of affordability and reliability for each package.

AI tools like Luma can help. Working together with the EasyPost shipping API, Luma is an AI strategist that provides deep insights into your current shipping strategy, offers data-backed recommendations to save time and money, and applies those changes to improve your shipping.

Frequently asked questions

Still have questions? We have answers!

How is AI used in warehouses?

AI is used in warehouses to improve processes like inventory management, order fulfillment, equipment maintenance, and workforce scheduling.

How long does AI implementation typically take?

The timeline for AI implementation varies based on the complexity of the system and the size of the warehouse; it often takes anywhere from a few months to over a year to fully integrate.

What kind of ROI can businesses expect with AI?

Businesses can see significant ROI with AI through reduced operational costs, higher efficiency and accuracy, and better decision-making. The exact return on investment will vary based on the organization and the AI system.